EVOLUTION

Our company history

The history of the company began in 2000. Three inventors – Alexander Scerbina, Leonid Nikitin and Mikhail Stetzurin embarked on the development of an efficient and inexpensive wind turbine, which would operate at low wind speed conditions that are so characteristic for Latvia.

2000

The inventors concluded that such a result could only be obtained by using the theory of aircraft-bladed machines in a turbine with a vertical axis of rotation. Their work began by defining the blade’s profile, determining the optimal characteristics of the lattice-like rotorblocks mathematically. Afterward, more than 100 types of blades with different profiles and curvatures were made and tested, and finally, the optimal blade profile was found. Having solved the task of turbine design, further research was still required to test the wind turbine in a wind tunnel.

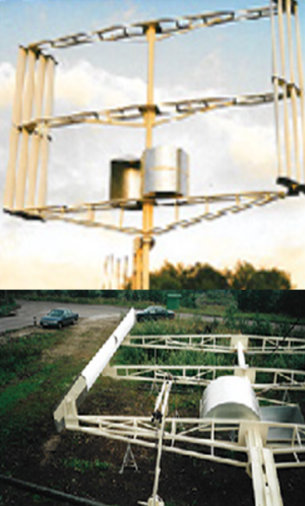

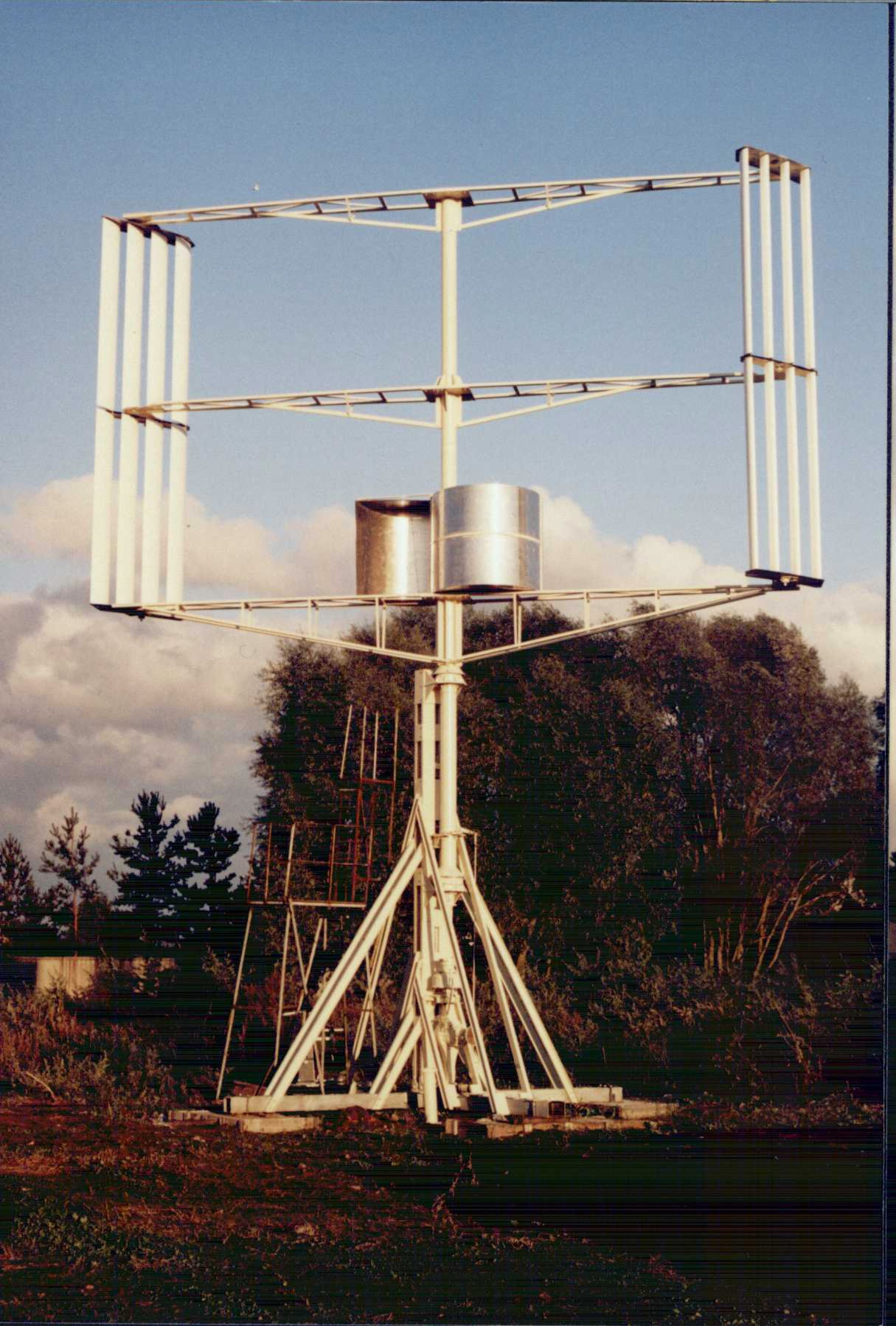

2002

After the successful completion of wind tunnel tests in 2002, the inventors built the first full-scale turbine with a rotor of 10.6m X 6m, attracting the help of some interested enthusiasts. What was unique about this design, is that it had no generator. The efficiency of the turbine was determined using tensometry and full-scale test results fully confirmed the findings obtained in the wind tunnel.

2004

In 2004 the second turbine was built, with a 6m x 6m rotor, a 12m high tower, and a 12 kW generator, constructed by the Riga Electromechanical Plant. The second prototype becomes the breakthrough proof of concept of the new design.

2007

In 2007 a third turbine was built, with a 9m x 7m rotor, a 12m high tower, and a generator and inverter from the Swedish company BEVI.

2009

In 2009 a fourth turbine was built and tested. With this prototype we conducted a series of operation tests, and elaborated the on-grid connection, as well as tested the wind turbine performance in different surrounding conditions.

2012

In 2012, fifth turbine was built, with a 7.6m x 7.5m rotor, a 12m high tower, a 60 kW generator on permanent magnets, and a 60 kW inverter by ABB. With this turbine we confirmed our performance for a 60kW as well.

2013

In 2013, a sixth turbine was built, with a 7.6m X 7.5m rotor, a 12m high tower, a 20 kW generator on permanent magnets, and a 20 kW inverter by ABB. The turbine was sent and installed in NREL USA, and we began the first part of NREL testing.

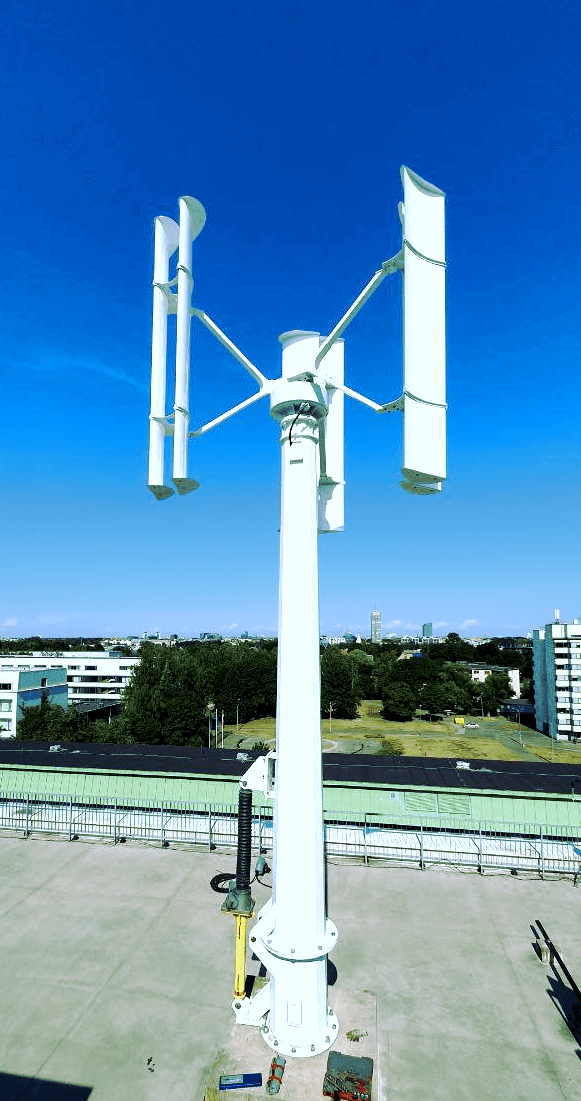

2014

In 2014, a seventh turbine was built, with a 3m X 3m rotor, a 12m high tower, a 3 kW Chinese generator on permanent magnets, and a 3 kW inverter from the Japanese company YASKAWA. The rotor grid is modified to include three blocks of two blades. By that we confirmed: for wind turbines under 10 kW our technology is the best in that exact blades formation.

2015

In 2015, an eighth turbine was built, with a 7.6m x 7.5m rotor, a 12m high tower, a 20 kW generator on permanent magnets from the Danish company DVE, and an inverter of 20 kW from the Italian company Bonfiglioli. This turbine was build specially for an alongside testing with the one in NREL.

2016-2020

Since 2016, we have mastered the best possible algorithms for turbine management. We have also completed the second round of testing all possible interaction scenarios between the generator and inverter, using our own know-how and proprietary turbine management system. Additionally, we completed the following interoperability testing:

- In 2016 we have tried and tested interoperability of motor-generator ABB 60 kW and ABB 60 kW inverter, as well as motor-generator ABB 20 kW and ABB 20 kW inverter.

- In 2017 – motor-generator ABB 20 kW and JASKAWA 20 kW inverter.

- In 2018 – motor-generator ABB 20 kW and Bonfiglioli 20 kW inverter.

- In 2019 – generator DVE 20 kW and JASKAWA 20 kW inverter with the usage of Datum Electronics sensor (in order to determine losses of passing energy to the grid).

- In 2020 – generator DVE 20 kW and Bonfiglioli 20 kW inverter with the usage of Datum Electronics sensor.

In 2020 the second turn of repeated testing of selected combination by NREL began.

2022

In 2022 we have got the final confirmation of our technology performance by NREL.

2023

In 2023

A research project with Riga Technical University (RTU) with our GWT-3(5)kW